H-profiles in fiberglass.

H-profiles are the main supporting element for virtually all GRP structures. Our stainless steel fiberglass H-profiles have a very long functional life, making them a cost-effective alternative to wood, concrete and steel. Minimal maintenance requirements, even in corrosive and aggressive environments.

GRP H-profiles are designed to withstand large spans and high loads, making them an obvious choice for load-bearing parts of GRP-based structures. With high stiffness and low weight, they offer an optimal combination of strength and material efficiency.

Like our other fiberglass profiles, the H-profile is virtually maintenance-free, has good chemical resistance and is easy to process on site – without the need for special tools. This makes it a time-efficient and cost-effective option in both new construction and renovation projects.

Typical applications include stairs, drainage systems, walkways, water and wastewater treatment plants, and substructures for GRP gratings and platforms in harsh and corrosive environments.

Advantages of GRP H-profiles:

- Corrosion-free

- Easy to machine on site, without welding or other special tools

- UV and chemical resistant

- Electrically insulating, does not conduct current

- High strength

- Long shelf life

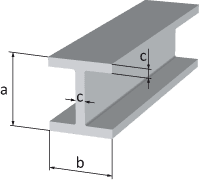

| a (mm) | b (mm) | c (mm) |

|---|---|---|

| 6.7 | 40 | 1.8 |

| 30 | 10 | 4 |

| 31.5 | 17 | 3 |

| 39 | 25 | 4 |

| 40 | 10 | 4 x 5 |

| 40 | 40 | 5 |

| 50 | 40 | 2.5 |

| 100 | 50 | 5 |

| 120 | 60 | 6 |

| 150 | 75 | 6 |

| 150 | 75 | 8 |

| 150 | 75 | 10 |

| 150 | 150 | 10 |

| 200 | 100 | 6 |

| 200 | 100 | 10 |

| 200 | 200 | 15 |

| 300 | 150 | 12 |

| 300 | 300 | 13 |

| 500 | 200 | 15 |

| 700 | 254 | 12,7 x 18 |